An Independent Thermasteel Distributor

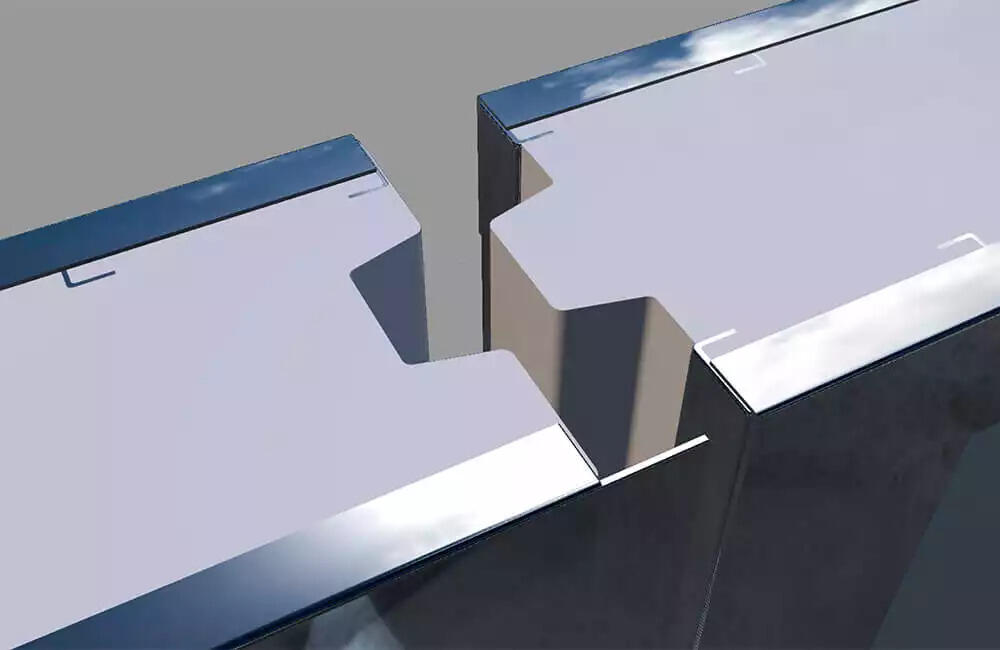

ThermaSteel’s patented composite joining technology bonds light gauge steel structural members together with EPS, delivering a stronger, lighter wall system which installs faster, and performing as structural framing, insulation, sheathing and vapor barrier — all in one

About Us

ThermaSteel panels are a FOUR-IN-ONE solution for the building industry. Our steel SIP panels perform structural framing, insulation, sheathing and vapor barrier, reducing labor cost and installation time by more than half! Our unique technology provides panels with a thermal break between the interior and the exterior of the wall, like no other SIP, making their energy efficiency even higher.ThermaSteel began manufacturing panels in Radford, VA in 1970. What makes us a world leader in the panel industry? Not only did we pioneer the technology, but we also have extensive experience (over 75,000 projects around the world) and we can do the entire building envelope – or as much of the building as you want us to do. We have panels for exterior and interior walls, floors, concrete floors, roofs, shear walls and even foundation panels.We manufacture commercial buildings, residential, tiny homes, tool sheds, freezers, net zero buildings, and passive nursing homes. We manufacture buildings for the military in multiple countries, in addition to aerospace, naval and other industrial applications. Nearly all our projects are custom designed for the specific desired application.

If you can sketch it – We can make it

Over the last 50+ years, we have developed 25 patents that allow us to design and shape the structure that YOU need. Our panels are high R-values (up to R61), compliant with ASHREA 90.1 and all are thermally broken. With a tight tongue and groove connection system, we exceed the requirements of the energy codes. The key is that our patented composite technology allows us to bond light-gauge steel with EPS to create composite material panels capable of carrying unusually heavy loads. Our panels are treated for smoke and flame retardancy, making the panels noncombustible assemblies. While the panels are safe for humans and do not off-gas, they are free of pests such as termites, bees, rodents, and more, since they do not offer any food value.We are a 100% waste-free production factory, with low carbon emission, and we incorporate recycled materials into the panels where possible.Check our resources page for certifications, including:IAPMO load bearing tables for II-V construction type

2hr fire test for a load bearing wall

Florida hurricane rating

Government vendor

9.5 Richter scale by Russia

Below grade application

In our user-friendly process, our drafts-people will work with your engineer and architect, and panelize your project into shop drawings to integrate rough openings, beams, and headers to allow you to construct the building of your dreams. The panels will arrive to your job site ready to be installed.

Energy Efficiency

With an effective R-Value of up to R-61 and no thermal bridging, our insulated panels will reduce heating and cooling costs by 75% or more over traditional construction methods and are well suited for Net-Zero and Passive House designs.

Sustainable & Safe

With a life expectancy of 425 years, our panels do not off-gas, are mold & mildew resistant, are fire resistant with low smoke and flame spread properties, are 100% recyclable, AND are produced with recycled materials in a zero-waste facility.

Unlimited Possibilities

No manufacturing limitations. If you can dream it, we can produce it! From simple sheds to custom homes, from hotels to mid- rise buildings, we do it all! Panel packages available for exterior walls, interior walls, below grade walls, floors, and roofs, including curved walls and openings.

Construction Efficiency

4-in-1 lightweight true load bearing panels reduce framing time by 50% translating into significant labor & equipment cost savings. Your project will be delivered pre-cut, diagrammed, and labeled for quick assembly.

Projects

The ThermaSteel Advantage - With more than 50 years of worldwide experience, we are the world leader in panelized building methods.

Commercial

Learn about the ThermaSteel panel system and the process of manufacturing your project.

About the Panels

If you are a builder, developer, architect or engineer learn more on code compliance and savings.

Residential

If you are a homeowner learn how ThermaSteel panel system can benefit your family.

Commercial Projects

Cost of Construction and Long-Term Maintenance Savings - In 1970, ThermaSteel introduced a new technology of bonding Light Gauge Steel [LGS] to Expanded Poly Styrene [EPS], creating the first pre-manufactured construction Structural Insulated Panel [SIP]. Today, 75,000 projects and 50+ years later, it is still the world leader in the industry, providing the entire building envelope, for building types I-V. Offering

Why Build Your Home with ThermaSteel Panels?

Highly Experienced - We have completed over 75,000 projects in the last 50+ years in the business. From commercial to residential, military or DIY, no design limitations.

Fast and Affordable - Building with ThermaSteel saves you time and money. Complete your house in half the time. Reduce your maintenance by 15% and downsize your HVAC by 50%.

Safe and Energy Efficient - Build a safer, healthier home. Our panels resists mold, mildew, black mold and even termites. Best of all, your home will save you 75% on energy bills for the rest of your life!

10 Years Warranty - All ThermaSteel panels come with a 10 year material warranty. We keep records for 25 years if you need to change or add another panel, we can get you going in hours.

Certified & Code Compliant - From hurricanes to earthquakes, energy codes, and fire, we have all the proper certifications in place to meet the demands of your project.

House Made of Steel - ThermaSteel panels are the best panel system in the world. All galvanized steel structure. Highly insulated and non-toxic. Earthquake and hurricane safe.

Professional Team - Building a house is complicated. Our professional team will work with your architect and engineer to assure you a successful project.

Environment Friendly - We are 100% recycled facility. Our main manufacturing component is steam and we generate zero waste. Even our raw materials are up to 20% recycled.

World Leading Product - We are the world leader of Steel Structural Insulated Panels (SIP). ThermaSteel panels are used by governments, home owners and militaries in over 83 countries around the world from the african desert to the arctic pole.

Why Build Your Project With ThermaSteel?

Whether your house is in warm Florida or cold Michigan, you want to save on energy bills and have a quiet, energy efficient home. ThermaSteel’s super-insulated xPanels technology, custom manufactured M-SIP / S-SIP thermally broken panels have super insulation performance, as high R-61. The result is significant. You can decrease the energy required to heat and cool your home by up to 75% - Sample BillSave big time. Panels arrive on-site ready to install. No additional structure, No insulation, No sheathing, and no vapor barrier are required: Four steps accomplished with each xPanel put in place. Save on multiple material shipments and reduce your labor from four or even five trades to only one framer.Our panels are like big building blocks, arriving marked and with all required accessories, even track and screws. Our drawings are labeled so that all you need to do is “drop in place” and fasten. We follow the construction and framing industry, using studs every 16″. So, if you are a handy man, and have some framing experience as a carpenter or in framing, training time is less than 2 hours.Quick and fast install – there is no special training required, nor power tools except for a screw gun. Install process is very quick. An average house is usually completed within 3 days (Exterior interior and roof panels) can be done by one framer and 2 helpers.If your project is Net-Zero or a Passive House, utilizing natural energy such as solar panels, due to the high efficiency of ThermaSteel xPanels, the energy requirement is less, resulting in less solar panels, which are more effective and your batteries last longer, saving initial investment costs and providing higher power output that can be then sold back to the grid in most locations.

Safety: Flame Spread and Smoke Development tests show that ThermaSteel xPanels are one of the safest ways to build, saving on home owners Insurance cost. More so, the panels are not off-gassing, carcinogens, pathogens, or allergens, resulting in a completely safe and heathy environment especially for kids sleeping long nights inhaling indoor air.Not a source of food for pests: Insects such as termites like to invade and live where they feed. Because ThermaSteel xPanels offer no attraction as a food source, building with ThermaSteel instead of wood is the best way to ensure pest-free living. If your project is in a termite zone – by using Panels you are safer. And, you’ve just eliminated the need for termite-killing poisons around your living area. Read more about termite hazardIf your project is on the coast, or in a Hurricane zone, our panels are rated and tested for the Miami Dade Hurricane wind and projectile protocol.Wood-based products have vulnerability to moisture, mold, and mildew. ThermaSteel panels are made of steel and EPS insulation, making them resistant to fungi and molds. So build a home with our S-SIP / M-SIP panels and be worry-free. Read more about wood vs steel panelsWe are pioneers in Eco-Friendly manufacturing. Our production facility is 100% recycled, waste free. Even our Light Gauge Studs consist of up to 20% recycled steel.If your project is in an earthquake zone – you are safe with us. ThermaSteel panels weigh on average 45 pounds each (4′ by 12′), being so light means they will not vibrate in a seismic event and will not crack. We have even tested and certified for Richter scale magnitude 9 earthquakes, from Russian lab tests.425 year life expectancy. How often do you see stick-built homes being torn down? The majority are less than 50 years old!Flexibility of design – if your project has curved walls, round windows – we have seen it and done it before. We have developed a technology that is literally limitless! ThermaSteel Panels arrive ready to assemble with all hardware included. All of the rough openings for windows and doors are pre-fabricated, made to meet the specifications of each window and door manufacturer. No measuring, no cutting, no scrap, no foam.

Flexibility

Design

Easy to read, customized “for your project” assembly drawings are furnished with each project. Each numbered panel on the drawing corresponds to the number written on each panel. Your assembly drawings are available several weeks before your panels arrive, so there is plenty of time to become familiar with the instructions and diagrams, and to call us with any questions. Every 6 Panels are bundled up according to the wall line up of your project.What about electricity and plumbing? every panel comes with 1″ x 2″ wire raceways 11″ from the bottom so you don’t need to drill studs. Cutting out the foam for plumbing is easy and can be done with a pocketknife of a hot knife cutter. Electrical boxes are attached to the studs as usual.

If you are asking yourself where is the catch?

We have been in business for more than 50 years. Way before any other panelized company even thought of starting. This process has been repeated on over 75,000 projects in over 83 countries all around the world. This means we’ve worked the bugs out of the process and it’s rare for something new to come up that we haven’t seen before.

Projects

The ThermaSteel Advantage - With more than 50 years of worldwide experience, we are the world leader in panelized building methods.

Panels

ThermaSteel’s patented composite joining technology bonds light gauge steel structural members together with EPS, delivering a stronger, lighter wall system which installs faster, and performing as structural framing, insulation, sheathing and vapor barrier — all in one.See the different types of ThermaSteel panels in application with this video (2 min):

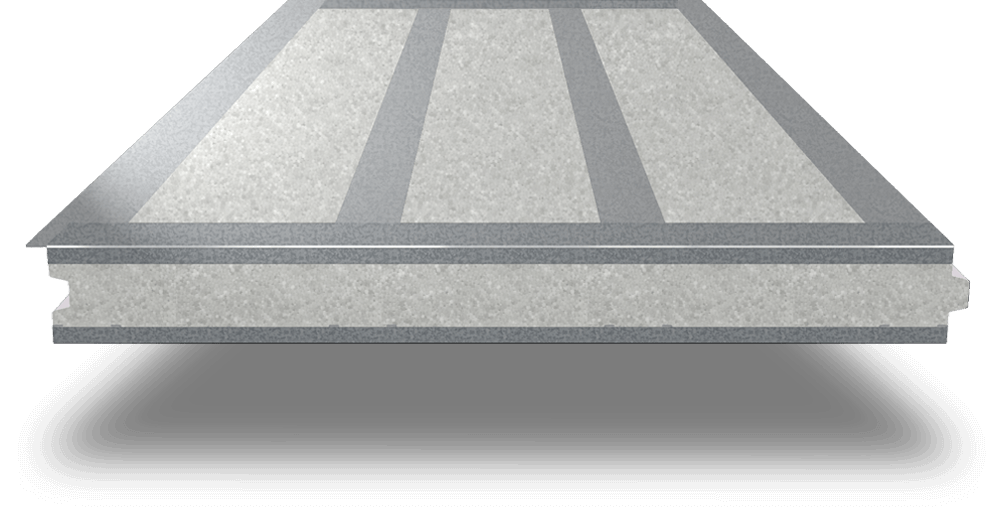

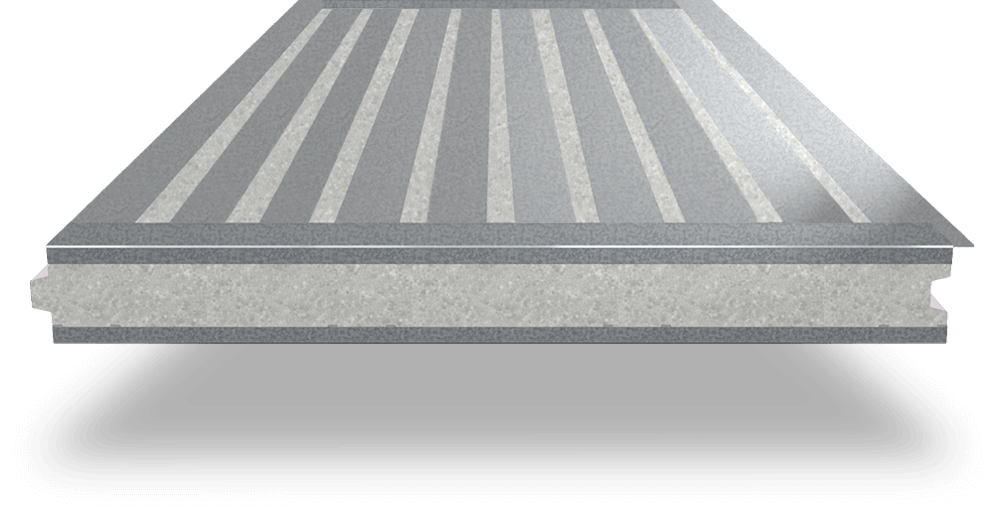

Panel – Exterior Wall Panel

Used mainly for exterior wall applications

5.5″ or 7.5″ thick, up to 4′ wide and 12′ tall

Effective thermal performance of R51 to R61

4 or 5 structural studs on both faces of the panel (16″ or 12″ o.c.)

Up to 42,000 plf load LRFD

Ready for direct application of final skin

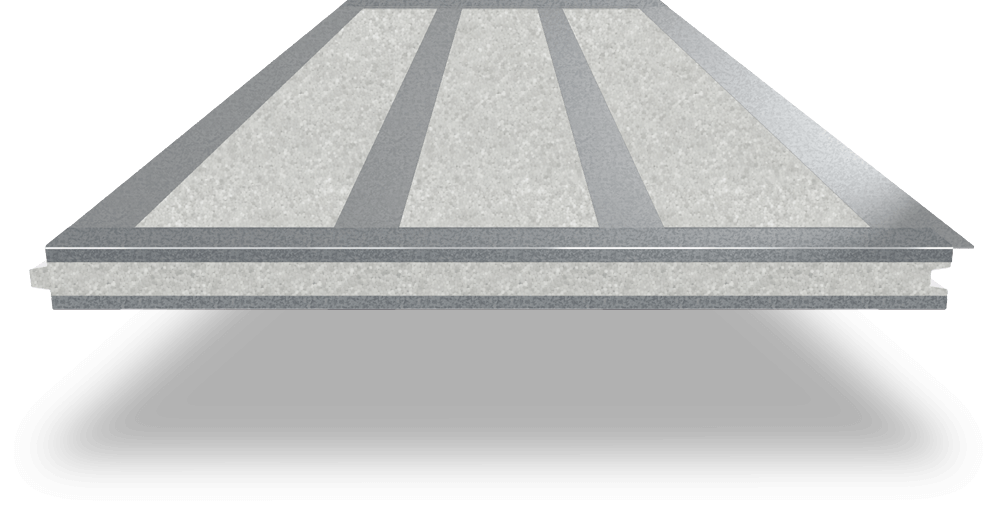

Panel – Interior Wall Panel

Used mainly for interior wall applications or tiny homes

3.5″ thick up to 4′ wide and 12′ tall

Effective thermal performance of R28

4 structural studs on both faces of the panel (16″ o.c.)

If you are looking for a quiet room or DIY, this is your panel!

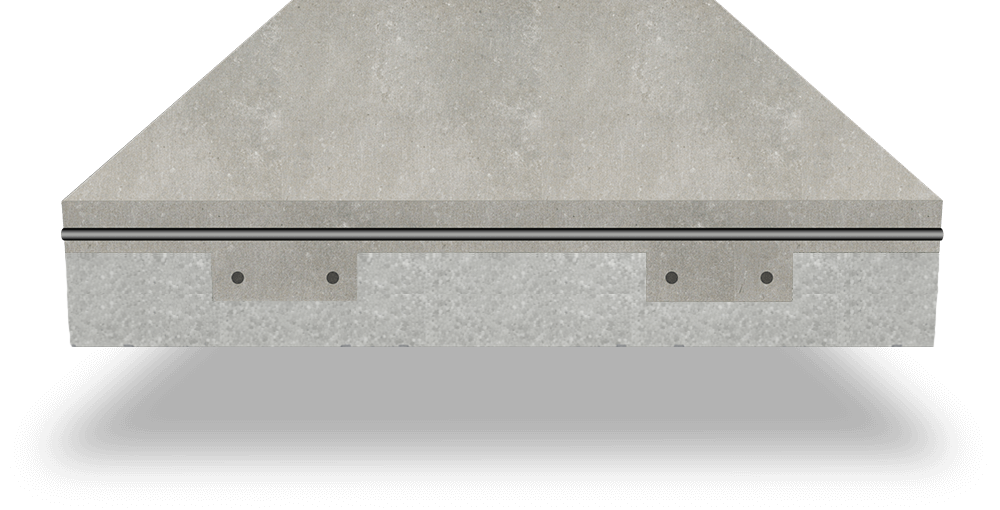

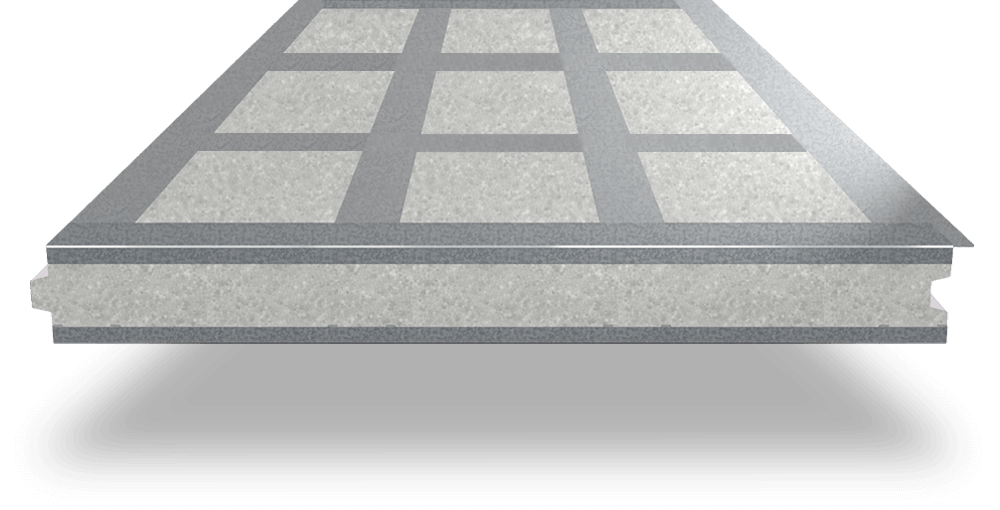

Panel – Concrete Floor Panel

Stay in place form for concrete slabs

7.5″ thick R58 insulation, 4′ wide 12′ long

Two 8″ wide channels for rebar in the reinforced beams

Capable of spanning up to 50 ft clear with minimum shoring

Reduces concrete by 40% (average section is 58 psf)

High STC rating fire stop between floors

Reduces labor time by over 60%

5 studs to hang ducts or attach sheathing directly

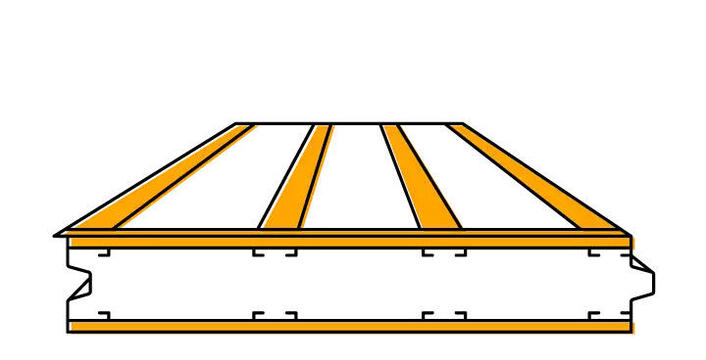

Panel – Roof Panel

5.5″ or 7.5″ thick up to 4′ wide and 12′ long

Effective thermal performance of R51 to R61

4 or 5 structural studs on both faces of the panel (16″ or 12″ o.c.)

Load bearing means we can reduce trusses by 2/3 (every 4-6 ft o.c.).

2 panels can connect directly allowing for cathedral ceilings and A frames without supports

Panel – Hurricane Panel

Designed, tested, and certified to withstand 185mph, including flying debris

5.5″ or 7.5″ thick up to 4′ wide and 12′ long

Effective thermal performance of R51 to R61

4 or 5 structural studs on the interior faces of the panel (16″ or 12″ o.c.)

11 studs on the exterior face making it projectile-safe

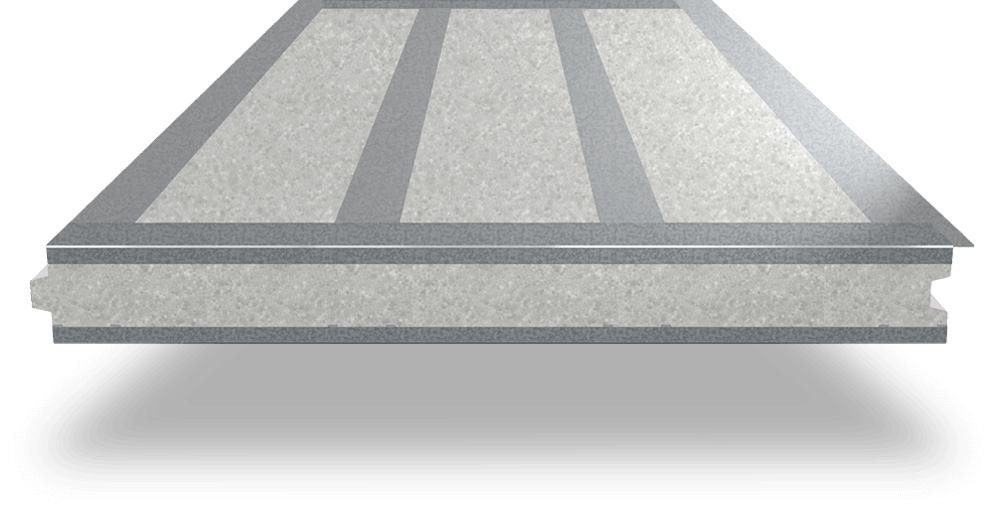

Panel – Shear Wall Panel

5.5″ or 7.5″ thick up to 4′ wide and 12′ tall

Thermally broken with three horizontal bracings

Effective thermal performance of R51 to R61

4 or 5 structural studs on both faces of the panel (16″ or 12″ o.c.)

Up to 2,420 plf with a 2.0 safety factor

Studs of ThermaSteel panels are turned sideways (creating a thermal break), orienting the strong side of the stud in the shear direction, effectively making every panel a shear panel.

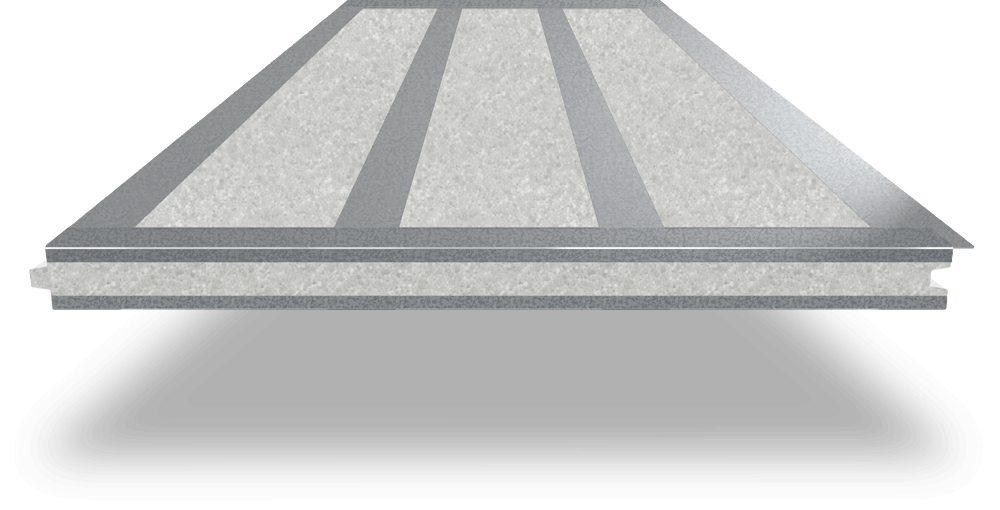

Panel – Below Grade Panel

Used for foundation, knee walls, and retaining walls

7.5″ thick 1.5 density up to 4′ wide and 12′ tall

Thermally broken with three sections and thermal performance of R61

4 or 5 structural studs on both faces of the panel (16″ or 12″ o.c.)

Check the below grade manual for design guidelines and limitations

Panel – Ceiling Panel

Used as interior application under the truss or on the bearing walls

3.5″, 5.5″ , or 7.5″ thick up to 4′ wide and 12′ long

Effective thermal performance of R28 to R61

4 structural studs on both faces of the panel (16″ o.c.)

Pre-chased and ready to directly attach sheathing.

LEED® – POTENTIAL CREDITS FOR THERMASTEEL PANEL USE

It is important to note that the below scoring is meant for reference only. Actual project scoring will depend on the individual rater, contractor, and other factors.

RESIDENTIAL PROJECTS: LEED for HOMES

EA – ENERGY and ATMOSPHEREPERFORMANCE PATHEA 1: Optimize Energy Performance: Maximum 34 PointsUsing the Performance Pathway, the building is awarded points based on overall energy performance, measured by a HERS index. A home’s HERS index is calculated by a certified energy rater and takes into account the insulation, results from a blower door test, HVAC, lighting, and other relevant information. LEED points are allocated on a scale ranging from 0 points for ENERGY STAR and 34 points for a net zero energy home. Homes must meet ENERGY STAR requirements as a prerequisite for this credit.PRESCRIPTIVE PATHEA 2.1: Insulation: Maximum 2 PointsContractors must install insulation that meets (or exceeds) the requirements of the 2004 International Energy Conservation Code (IECC) and are given points for exceeding this standard. Structurally Insulated Panels are listed as an exception to this requirement and must alternately pass a visual inspection using the ENERGY STAR SIP Visual Inspection Form.EA 3: Air Infiltration: Maximum 3 PointsWell-sealed, airtight ThermaSteel homes have a proven track record of achieving extremely low levels of air infiltration. Homes are awarded points based on their blower door test results, with a maximum of 3 points possible.MR – MATERIALS and RESOURCESMR 1.4: Framing Efficiencies: Maximum 3 PointsThe project is given one point for each SIP system used: walls, roofs, and floors. ThermaSteel panels are manufactured for all three usages.MR 1.5: Off-Site Fabrication: Maximum 4 PointsThis credit can be awarded to homes with pre-cut SIPS in the walls, roof, and floor. If SIPs are cut on site, or only used in walls and/or roof, no point should be awarded for this credit; points may be awarded in MR 1.4 instead.MR 2.2: Environmentally Preferable Materials: Maximum 2 PointsSIPs should be treated as two different components – framing and insulation. If the requirements for either or both components are met, points should be awarded accordingly. (MR 03 -04)MR 3.2: Construction Waste Reduction: Maximum 3 PointsUsing prefabricated SIP panels decreases the amount of on-site construction waste, helping contractors qualify for waste reduction points. Waste reduction points are given on a scale ranging from 0 to 3 depending on the amount of waste generated per square foot of the home.COMMERCIAL PROJECTS

ThermaSteel panels are used not only in residential projects, but also in commercial projects. Below are the potential credits for using ThermaSteel panels in your commercial projects when LEED 2009 for New Construction and Major Renovations rating system is used. However, it must be understood that the variables in commercial construction differ from one project to another vastly. Therefore, if you have a commercial project that seeks LEED certification, we can help you on a per-project basis.LEED 2009 (version 3.0) NEW CONSTRUCTION and MAJOR RENOVATIONSIt is important to note that the below scoring is meant for reference only. Actual project scoring will depend on the individual rater, contractor, and other factors.EA – ENERGY and ATMOSPHEREEA 1: Optimize Energy Performance: Maximum 19 PointsThermaSteel wall panels are ENERGY STAR™ compliant. The ThermaSteel panel provides not only structural integrity, but excellent insulation properties as well. The EPS component of the panel is solid (except where wire chases are incorporated) and does not provide voids or allow air movement through the walls. In a study conducted by Energy scientists at the Oak Ridge National Laboratory* the stated R-Value of virtually every product on the market evaluated in the “real world” of thermal breaks such as corners, windows, doors, and stud walls were drastically reduced – EXCEPT when using Structural Insulated Panels. For example: A 2” x 6” stud wall 24” on center with R-19 fiberglass batts tested out with an R-Value of 13.7. A Structural Insulated Panel wall tested at R- 21.7. That means that the Structural Insulated Panels outperformed a 2” x 6” stud wall by 58%!*ASHRAE Journal March 1996, Christian and KosnyMR – MATERIALS and RESOURCESMR 2: Construction Waste Management: Maximum 2 PointsThermaSteel panels produce little to no waste on the jobsite, since they arrive as numbered blocks ready for precise assembly.MR 4: Recycled Content: Maximum 2 PointsThermaSteel panels are assemblies that are made of steel studs and EPS infill. Steel is “Green” because it contains a minimum of 25% recycled steel and is 100% recyclable. The recycled content value of a material assembly is determined by weight. The recycled fraction of the assembly is then multiplied by the cost of assembly to determine the recycled content value.MR 5: Regional Materials: Maximum 2 PointsUse building materials or products that have been extracted, harvested, or recovered, as well as manufactured, within 500 miles of the project site for a minimum of 10% or 20%, based on cost, of the total materials value.RP – REGIONAL PRIORITYRP 1: Regional Priority: Maximum 4 PointsID – INNOVATION IN DESIGNID 1: Innovation in Design: Maximum 1 PointREFERENCES:https://www.energystar.gov/sites/default/files/asset/document/Inspection_Checklists.pdf (ENERGY STAR SIP Visual Inspection Form)http://www.usgbc.org/ShowFile.aspx?DocumentID=3638 (LEED for Homes “Search SIP”)http://www.usgbc.org/ShowFile.aspx?DocumentID=8868 (LEED 2009 for New Construction and Major Renovations)Prepared by: Nida DeBusk, Intl. Assoc. AIA, CSI, CDT, LEED AP BD+Cnb